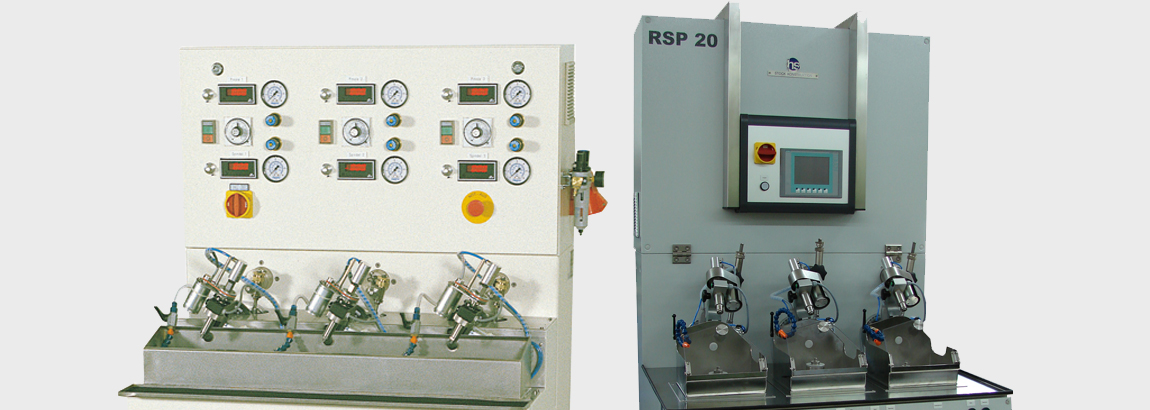

Machines modernization is an economical alternative

Mostly older machines are mechanically in good condition, but the control or drive area are no longer state of the art or are unreliable.

By replacement and reinstallation of controls or drives of the latest generation - the same technology that was previously used - achieves a standard that is close to a new machine or system. An additional mechanical overhaul and modernization can be quoted on request as a complete package at a fixed price. With retrofit you can exceed the former performance of your used machine and installing modern controls improves monitoring functionality.

By replacement and reinstallation of controls or drives of the latest generation - the same technology that was previously used - achieves a standard that is close to a new machine or system. An additional mechanical overhaul and modernization can be quoted on request as a complete package at a fixed price. With retrofit you can exceed the former performance of your used machine and installing modern controls improves monitoring functionality.

We can modernise and adapt your old machine or system to the new realities of the technology.

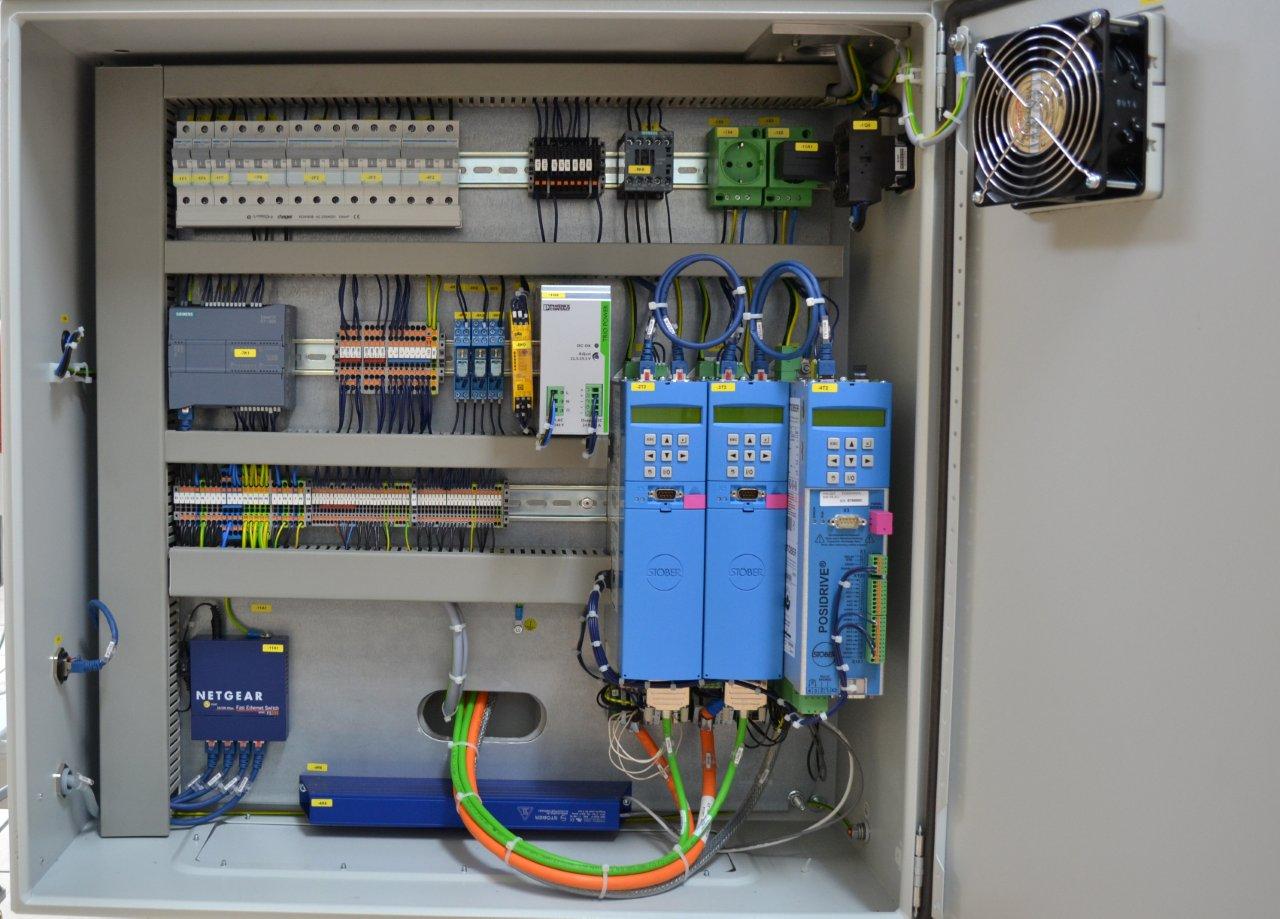

Our most commonly used tools are:

SIMATIC controllers (PLCs)

(Simatic S5, Simatic S7, Simatic S7 Basic)

SIMATIC HMI operator control and monitoring systems

(ProTool, WinCC flexible, WinCC Basic)

SIMATIC NET communication systems

(Profibus, Ethernet, Profinet)

Power Automation

(CoDeSys, HMI)

3S software

(CoDeSys, HMI, Motion)

Net communications

(Can, Serkos)

SIMATIC controllers (PLCs)

(Simatic S5, Simatic S7, Simatic S7 Basic)

SIMATIC HMI operator control and monitoring systems

(ProTool, WinCC flexible, WinCC Basic)

SIMATIC NET communication systems

(Profibus, Ethernet, Profinet)

Power Automation

(CoDeSys, HMI)

3S software

(CoDeSys, HMI, Motion)

Net communications

(Can, Serkos)